From Fly Ash to Silica Fume: A Friendly Guide to Pozzolanic Materials in Concrete

May 2, 2025

A Complete Guide to Home Demolition in India: Policies and Procedures

May 2, 2025Table of contents

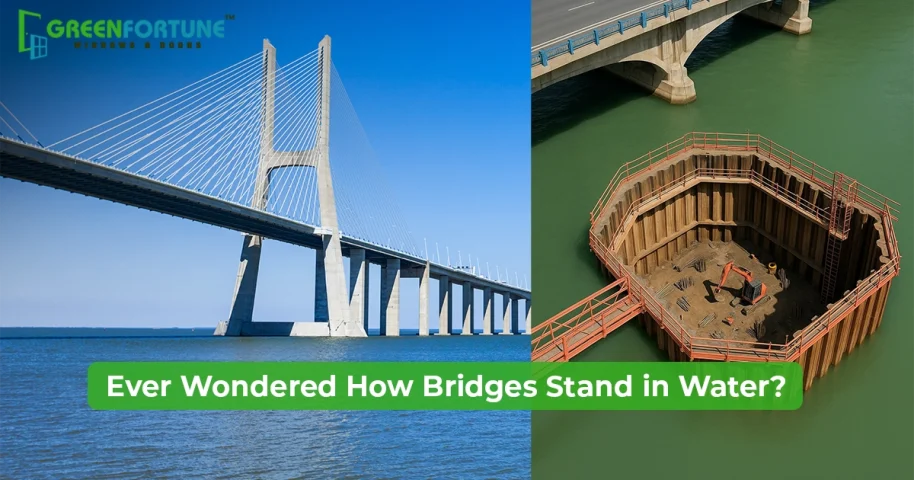

Ever looked at a massive bridge stretching over a river and wondered, “How on earth did they build the foundation under all that water?”

If you have wondered how engineers build sturdy foundations underwater or in areas with soft, unstable soil, you are not alone. That’s a fascinating construction technique known as pneumatic caissons.

Unless you’re deep into construction or civil engineering, the term “pneumatic caisson” probably sounds like something out of a sci-fi movie. But it’s a game-changer in the world of building.

Want to know more? Let’s find out!

What Is a Pneumatic Caisson?

A pneumatic caisson is a large, pressurised chamber used in construction projects, primarily to create deep foundations underwater or in soft soil. It uses air pressure to keep water, soil, and mud out of the working area, allowing workers to dig and build in conditions that would otherwise be dangerous or unmanageable.

Pneumatic caisson consists of a watertight chamber that is pressurised to withstand the weight of the surrounding water or soil. The chamber is typically made of steel and is lowered into the ground or underwater, with the workers working inside under high air pressure.

Pneumatic caissons are often used for projects such as bridge piers, dock foundations, and tunnel shafts, where building on soft or submerged land is necessary.

Components of a Pneumatic Caisson

Understanding the components of a pneumatic caisson is crucial to grasping how this engineering marvel works. Here’s a breakdown of its key components:

Component | Description |

Caisson Shaft | The vertical or inclined shaft that holds the pressurised chamber. |

Working Chamber | The airtight, pressurised space where workers perform excavation and construction. |

Compressor System | A system of air compressors that maintains the high air pressure inside the caisson. |

Air Locks | These are used to regulate the movement of workers in and out of the chamber safely. |

Sinking Mechanism | A system that helps the caisson sink into the soil or underwater by adding weight or using controlled explosions. |

Discharge Pipes | Pipes are used to remove water, mud, and other debris from the chamber. |

How Does It Work?

The process of pneumatic sinking involves lowering the pressurised chamber into the desired location. Here's how it works:

- Setting up the Caisson: First, a pneumatic caisson is placed in the area where construction is planned. The chamber is sealed, and air is pumped in to create a higher air pressure inside compared to the surrounding environment.

- Sinking the Caisson: The caisson is then gradually sunk into the ground or underwater. The higher internal air pressure keeps out water and mud, ensuring that the workers can operate in a dry, safe environment.

- Excavation and Construction: Workers inside the pressurised chamber excavate the soil and debris below them. The material is removed through discharge pipes, and the caisson continues sinking deeper until it reaches the required depth for the foundation.

- Final Setup: Once the caisson has sunk to the desired level, construction of the foundation can begin. The caisson remains in place, often reinforced with concrete or other building materials, forming the base for the structure above.

How does a pneumatic compressor work?

A pneumatic compressor maintains consistent air pressure inside the caisson. The compressor forces air into the chamber, which is crucial for preventing water and soil from entering and creating a dry and stable environment for workers to operate in.

Where Are Pneumatic Caissons Used?

Pneumatic caissons are primarily used in construction projects where the site is underwater, in wet or soft soil, or places with unstable ground. Some common applications include:

- Bridge Foundations: Pneumatic caissons are often used in the construction of bridge piers, where the foundations need to be submerged below water levels.

- Dams and Locks: In the construction of dams and locks, pneumatic caissons help provide a strong foundation in areas where the soil or underwater conditions are challenging.

- Tunnels: Pneumatic caissons are essential for creating safe shafts for tunnels, particularly in places where the ground is wet or unstable.

- Docking and Pier Construction: In maritime construction, pneumatic caissons help create the foundations for piers, docks, and harbours, where the caisson sinks below the water level to provide a stable base for the structure.

Advantages of Pneumatic Caissons

There are several reasons why pneumatic caissons are widely used in difficult construction environments. Here are some of the key advantages:

- Enables Construction in Challenging Environments: Pneumatic caissons allow construction to take place in wet, unstable, or underwater conditions that would otherwise be impossible to manage.

- Worker Safety: The pressurised environment inside the caisson protects workers from external pressure, such as water or mud, making the working conditions much safer compared to other underwater construction methods.

- Precise Excavation: Pneumatic caissons provide a controlled environment for excavation, allowing workers to dig to precise depths and maintain the integrity of the structure being built.

Also Read: River Sand vs M Sand: Which is Better for Your Construction Needs?

Challenges and Considerations

Despite their advantages, pneumatic caissons come with a set of challenges and considerations:

- High Cost: The setup of pneumatic caissons can be expensive due to the need for specialized equipment and technology.

- Risk of Decompression Sickness: When workers exit the pressurized caisson, they must undergo a decompression process to avoid decompression sickness (the bends), which can cause serious health issues.

- Time-Consuming: The process of sinking the caisson and maintaining the necessary air pressure can be slow, which might delay the overall construction timeline.

Safety Measures in Pneumatic Caisson Work

Safety is a top priority when working with pneumatic caissons, given the risks involved. Here are some essential safety measures that must be followed:

- Controlled Decompression: Workers must undergo a gradual decompression process when leaving the pressurized environment to prevent decompression sickness.

- Regular Monitoring: Air pressure and oxygen levels inside the caisson must be regularly monitored to ensure a safe working environment.

- Emergency Air Supply: An emergency air supply system should be in place to provide fresh air in case of compressor failure or other emergencies.

- Proper Training: Workers should be trained in the use of safety equipment and emergency protocols, including how to exit the caisson in case of an emergency.

Final Words

So, there you have it, a deep dive into pneumatic caissons. They might sound super technical, but at the heart of it, they’re just clever solutions for building in places where water and soft soil would normally make construction a nightmare.

If you’re planning a big project, understanding how pneumatic caissons work can help you ask the right questions, plan better, and avoid surprises!

Enhance Your Home Construction with Sustainable Solutions

As you start your construction journey, whether it's a foundation or any other project, make sure to prioritize quality and sustainability. GreenFortune offers a range of energy-efficient uPVC doors and windows that are designed to provide durability, security, and aesthetic appeal to your home. These products are ideal for both modern and traditional homes, ensuring you get the best in both design and function.

Explore GreenFortune’s products today and elevate your construction project with top-quality, eco-friendly solutions.

FAQs

Q1: How long does it take to complete a pneumatic caisson operation?

It depends on the depth and soil condition, but it can take anywhere from several weeks to a few months. Time is also influenced by weather, equipment efficiency, and how easily the caisson sinks. Unlike standard excavation, this process is slower due to the safety protocols and technical requirements involved.

Q2: Can pneumatic caissons be customised for different site conditions?

Yes, engineers can tweak the size, air pressure levels, and structural design based on soil type, depth, and water pressure. This flexibility makes them suitable for everything from riverbeds to coastal infrastructure. It’s one of the reasons they’ve remained a trusted solution for decades.

Q3: Where are pneumatic caissons typically used?

Pneumatic caissons are commonly used in bridge foundations, tunnel shafts, dams, and pier construction, especially in areas with water or unstable ground. They're also preferred in projects where precision and long-term durability are critical, such as metro systems and offshore structures.