Everything You Need to Know About Frameless Shower Doors: Custom Designs, Installation Tips, and Benefits

December 23, 2024

Why Choose UPVC for Your Modular Kitchen Cabinets?

December 24, 2024How glass is made is an amazing material we see and use every day. It’s in the windows of our homes, the screens of our smartphones, mirrors, bottles, and even in-car windshields. But have you ever stopped to think about how it is made? Surprisingly, the glass starts as something very ordinary sand. Let’s take a closer look at the fascinating process of how this common material transforms into the clear, shiny substance we use so much in our lives.

What is Glass?

Believe it or not, glass is made from melted sand. To make glass, ordinary sand is heated until it melts and becomes a liquid. But this doesn’t happen easily, sand melts only at an extremely high temperature of about 1700°C, so it’s not something you’ll see happening on a beach!

When the melted sand cools, it changes completely and doesn’t turn back into the rough, grainy stuff it started as. Instead, it forms a new material with a unique structure. Interestingly, even though the cooled sand looks and feels solid, it isn’t a true solid. Scientists call it an amorphous solid, meaning it’s like a mix between a solid and a liquid. It has some of the order found in solids but also the random arrangement of molecules found in liquids.

Glass is so popular in our homes because it has many useful features. It’s clear, so we can see through it, and it’s affordable to produce. It’s easy to shape while it’s melted and stays strong when cooled. It can handle heat well, doesn’t react with food or other substances (like in glass jars), and can be recycled over and over again without losing quality.

This makes glass a truly amazing and versatile material that’s perfect for many everyday uses!

Source: Pinterest

How is Glass Made?

In 1945, US scientists tested a prototype atomic bomb in New Mexico, where the intense heat turned sand into glass. Thankfully, glassmaking today is far simpler, though it still requires high temperatures.

Commercial glass is made by melting sand, recycled glass, soda ash, and limestone. Soda ash lowers the melting point of sand, saving energy, but makes the glass water-soluble, which limestone prevents. This creates soda-lime-silica glass, the most common type used in bottles, windows, and more.

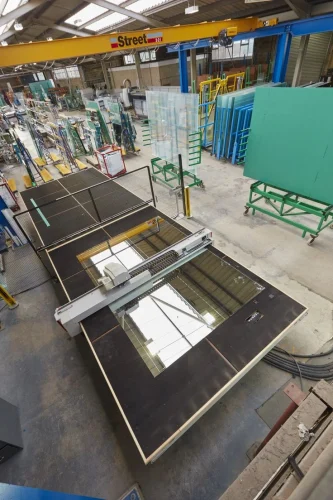

Molten glass can be shaped by pouring it into moulds, floating it on molten tin to create flat sheets, or blowing it into unique forms using a pipe and air.

Also read: What are the different types of aluminium windows?

The Process of Making Glass

It begins with gathering raw materials like silica sand, soda ash, and limestone, which are mixed in precise proportions. The mixture is then heated to around 1,700°C to form molten glass. Once melted, the glass is refined by removing impurities and air bubbles for a clear product. It is shaped using techniques such as blowing, pressing, or rolling, depending on its intended use. After shaping, the glass is slowly cooled in a process called annealing to relieve internal stresses. Finally, the glass is cut, polished, and sometimes coated to enhance its properties.

Adding chemicals to glass during the manufacturing process alters its properties in various ways.

- Green-tinted Glass: This type of glass is made by adding iron and chromium-based chemicals to the molten mixture, giving it a distinctive green colour. These chemicals are often used in the production of bottles, jars, and other containers.

- Oven-Proof Glass: To create glass that can withstand high temperatures without breaking, boron oxide is added. This makes the glass resistant to thermal shock, making it perfect for kitchenware such as baking dishes and laboratory glassware.

- Lead Crystal: Adding lead oxide to the glass mixture makes it much easier to cut and shape. Lead crystal is highly prized for its clarity and brilliance, and it sparkles with vibrant colours as light passes through it. It is commonly used in fine glassware, such as wine glasses and chandeliers.

Source: Pinterest

Specialty glass types are also produced for specific applications:

- Bulletproof Glass: Bulletproof Glass is made by layering multiple sheets of glass and plastic, which are bonded together to form a strong and flexible material. This composite structure helps absorb and dissipate the impact energy of a bullet, making it ideal for use in vehicle windows, security buildings, and banks.

- Toughened Glass: Toughened glass is produced by rapidly cooling molten glass, a process known as tempering. This rapid cooling increases the strength of the glass, making it more resistant to breaking or shattering. Toughened glass is commonly used in car windshields, shower doors, and phone screens.

- Stained Glass: Stained glass is made by adding metallic compounds, such as copper or silver, to molten glass to give it vibrant colours. The different metals produce various hues, from deep blues and reds to greens and purples. Stained glass is often used in decorative windows, church windows, and artwork.

Also read: Top 10 latest window designs in uPVC windows for your home

How Glass is Made up of Variants

Different types of glass are created by altering the raw materials or the manufacturing processes, allowing for various properties and uses.

- Tempered Glass: This type of glass is strengthened by a process called tempering, which involves rapidly cooling molten glass. The quick cooling makes the glass much stronger and more resistant to breakage or shattering.

- Coloured Glass: It is created by adding metal oxides to the molten mixture during the manufacturing process. These metallic compounds impact vibrant colours on the glass, such as blue, green, red, and amber. The type of metal oxide used determines the specific hue.

- Insulated Glass: It is also known as double-glazed glass, and is composed of multiple layers of glass with an insulating air gap between them. This design helps improve the thermal efficiency of the glass by reducing heat transfer. It is particularly useful in windows, doors, and facades, as it helps maintain indoor temperatures, reduces energy consumption, and provides better sound insulation.

Also read: A complete guide to choosing the perfect aluminium door for your home

The Role of Glass in Modern Life

Glass plays a vital role in modern life, thanks to its transparency, durability, and versatility. In architecture, it is widely used for windows, facades, and insulation, allowing natural light while enhancing energy efficiency. In technology, glass is essential for smartphones, tablets, and fibre-optic cables, providing clarity and strength for modern devices.

The automotive industry relies on tempered and laminated glass for safety, while smart glass offers adjustable transparency for added functionality. In healthcare, glass is indispensable for medical devices, lab equipment, and pharmaceutical packaging, ensuring purity and safety.

It also contributes to renewable energy by protecting solar panels and improving energy efficiency in buildings. Beyond its practical uses, glass adds beauty to art and daily life, from stained glass to heat-resistant cookware. With continuous innovation, glass remains indispensable across industries and everyday applications.

Source: Pinterest

Conclusion

The journey of how glass is made from sand showcases the marvel of human ingenuity. Through centuries of innovation, this simple yet intricate process has transformed an abundant natural material into one of the most versatile substances on Earth.

By understanding how glass is made, we gain a deeper appreciation for the material that surrounds us every day.

GreenFortune: High-Quality uPVC Windows for Every Home

At GreenFortune, we provide premium uPVC windows designed to combine durability, style, and affordability. Our range includes versatile designs to suit all types of homes, ensuring both aesthetic appeal and long-lasting performance.

Contact us to learn more about our uPVC window options. Whether you're building a new home or upgrading your current space, our solutions enhance comfort, energy efficiency, and the overall look of your interiors.

Frequently Asked Questions (FAQs)

What is the best soil for making glasses?

The best soil for making glass is silica sand, as it has a high percentage of silicon dioxide, which is essential for glass production. This type of sand melts at high temperatures, forming molten glass.

Can glass be made without sand?

While sand is the primary ingredient for making glass, it is possible to make glass using other raw materials, such as recycled glass or soda ash. However, silica sand remains the most common and essential component.

What is the natural colour of glass?

The natural colour of the glass is usually a slight greenish or grey tint due to the presence of iron impurities in the raw materials, particularly in silica sand. However, glass can be made colourless or dyed in various colours depending on the additives used during production.