How Much Does Marble Flooring Cost Per Square Foot?

April 28, 2025

How much do POP and Gypsum false ceilings cost per square foot?

April 29, 2025Imagine an expanding construction company struggling with selecting suitable building materials for expanding its projects. Cement block types stand out among all of their alternatives as reliable and cost-effective options.

However, their range of solid, hollow, and lightweight options can leave even experienced builders feeling confused as to which are best cement block types suited for them.

In this guide, we'll cover various types of cement blocks and their advantages, with an eye toward helping businesses attain long-term, high-quality construction results.

Table of contents

- What are Cement Blocks?

- The Role of Cement Blocks in Construction

- Various Types of Cement Blocks

- Considerations While Selecting Cement Blocks

- Using the Appropriate Cement

- Future Trends in Cement Block Manufacturing

- Conclusion

- Discover GreenFortune - Your Trusted Partner for Top-quality uPVC Windows and Doors

- FAQs:

What are Cement Blocks?

Cement blocks are precast concrete building units crafted with cement, sand, aggregate, and water that offer increased structural strength as compared to traditional bricks. Cement blocks come in various shapes and sizes that meet different construction needs.

The Role of Cement Blocks in Construction

Cement block types have long been recognized for their use as an efficient building material that offers durability at a reasonable cost. Their strength protects the structures from weather, pests, and fire. They require less maintenance over time, and their versatility enables builders to address a range of applications, from load-bearing walls to decorative paving projects.

Read more - Best Texture Design for Front Elevation

Various Types of Cement Blocks

Here is a curated list of the cement block types -

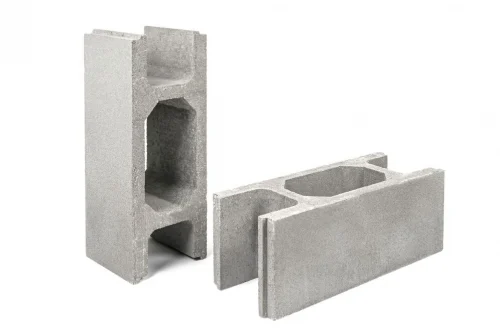

Solid Cement Blocks

Renowned for their strength and density, solid cement blocks are commonly used for load-bearing walls, foundations, and other structural applications that demand long-term performance in challenging environments.

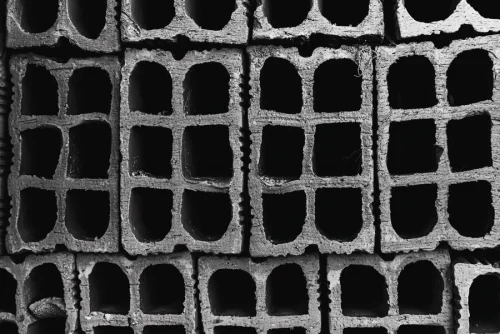

Hollow Cement Blocks

Hollow cement blocks types feature cavities that reduce weight and improve insulation. They are popularly used as partition wall components due to their lower density, which allows them to be easily handled and installed.

Furthermore, their large voids can accommodate plumbing and electrical systems and help speed up construction processes.

Asia Pacific accounted for 58.5% of the global hollow concrete blocks market revenue in 2022, driven by rapid urbanization and infrastructure development.

Aerated Autoclaved Concrete (AAC) Blocks

AAC blocks are lightweight and eco-friendly building materials that are created using cement, lime, fly ash, and aluminum powder, which react together to form a strong and porous structure that reduces energy efficiency while simultaneously decreasing environmental footprint.

Builders appreciate them due to their energy savings potential and reduced environmental impact.

Paving Blocks

Specifically created for landscaping and outdoor use, paving blocks offer durable yet visually appealing surfaces for driveways, walkways, and patios.

Available in various shapes and colors to allow creative design while remaining structurally sound.

Lightweight Concrete Blocks

Lightweight blocks combine reduced weight with sufficient strength, making them suitable for non-load-bearing walls or applications where ease of handling is key. Many lightweight blocks feature materials like expanded polystyrene beads or pumice to lower their density.

Considerations While Selecting Cement Blocks

Here are the points that you can consider while you select cement bricks

Strength and Durability

When selecting cement block types for your project, keep in mind the requirements of its structure. Load-bearing walls may need solid blocks capable of withstanding high compression forces, while partition walls may use lighter, hollow ones.

Thermal and Acoustic Insulation

Certain cement block types, such as AAC and hollow cement blocks, offer better heat and sound insulation than others, making them perfect for buildings in hot climates or bustling urban environments that want to maximize comfort while maximizing energy efficiency.

Eco-Friendly Blocks

Selecting eco-friendly cement block types, such as AAC blocks or those made from recycled materials, can significantly lower the environmental footprint of any project. Builders increasingly turn to this option in order to meet sustainability goals and regulatory requirements.

Read more - Different Types of Construction Bricks

Best Practices for Utilizing Cement Blocks

Proper Curing and Maintenance Proper curing and maintenance are crucial in order to reach the strength and durability intended by cement block types. Be sure to follow any recommended curing times or methods in addition to ongoing sealing or cleaning maintenance for extended durability.

Using the Appropriate Cement

The type of cement used in block composition greatly impacts its performance. High-strength cement may be needed for heavy structural elements, while general-purpose cement will suffice in non-load-bearing partitions. Selecting an appropriate cement will guarantee optimal results.

Read more - Best Cement Type for India

Future Trends in Cement Block Manufacturing

The cement block industry is evolving to meet modern construction challenges. Innovations such as 3D printing, alternative binders, and carbon-neutral production processes are revolutionizing how these blocks are produced.

Builders can look forward to more efficient manufacturing techniques, eco-friendly materials, and advanced performance characteristics of cement block types in the years ahead.

Conclusion

Cement blocks have long been considered one of the cornerstones of modern construction, providing durability, versatility, and cost-efficiency.

By understanding their various forms, applications, and best practices for use, builders can make informed choices to enhance both project quality and sustainability.

With innovations shaping the future of cement block manufacturing, now is an opportune time to embrace these reliable building materials and achieve long-term construction success.

Discover GreenFortune - Your Trusted Partner for Top-quality uPVC Windows and Doors

GreenFortune is your go-to solution for providing energy-efficient windows and doors with visual appeal, long-term performance, and premium comfort for your home improvement plans.

Green Fortune windows and doors, made with premium UPVC solutions specifically for each application, will add visual appeal and provide long-term performance.

Choose GreenFortune now and experience our extraordinary quality, design, and customer service.

FAQs:

1. Can cement blocks types be customized in size and shape to fit my specific construction project needs?

While standard cement blocks come in standard sizes, many manufacturers now offer custom molds to create customized blocks tailored specifically to the project requirements of architectural design and construction, offering more design freedom in architecture.

2. How well do cement blocks perform in extreme weather conditions?

Cement blocks treated with weather-resistant coatings remain strong structures even in hot and cold climates, while proper sealing and insulation help increase resistance against freezing, thawing, and moisture penetration.

3. Are cement blocks considered eco-friendly building materials?

Cement blocks made with alternative materials such as fly ash or recycled aggregates can substantially lower their carbon footprint, and modern manufacturing techniques are continuously improving the sustainability of cement blocks.

4. Can lightweight concrete blocks be used in load-bearing walls?

While lightweight concrete blocks are most often valued for their ease of handling and insulation properties, some varieties have also been reinforced to meet load-bearing applications. It is important to check the manufacturer specifications to determine whether any particular block type meets any structural requirements before purchasing one.

5. What's the difference between solid cement blocks and paving blocks?

Solid cement blocks are dense and usually used for structural components like walls and foundations, while paving blocks are made specifically to withstand outdoor surfaces like driveways and walkways, such as driveways. Their manufacturing ensures durability against wear and tear as well as aesthetic features like color options.