River Sand vs M Sand: Which is Better for Your Construction Needs?

February 13, 2025

Why Red Oxide Flooring is Making a Comeback in Modern Homes

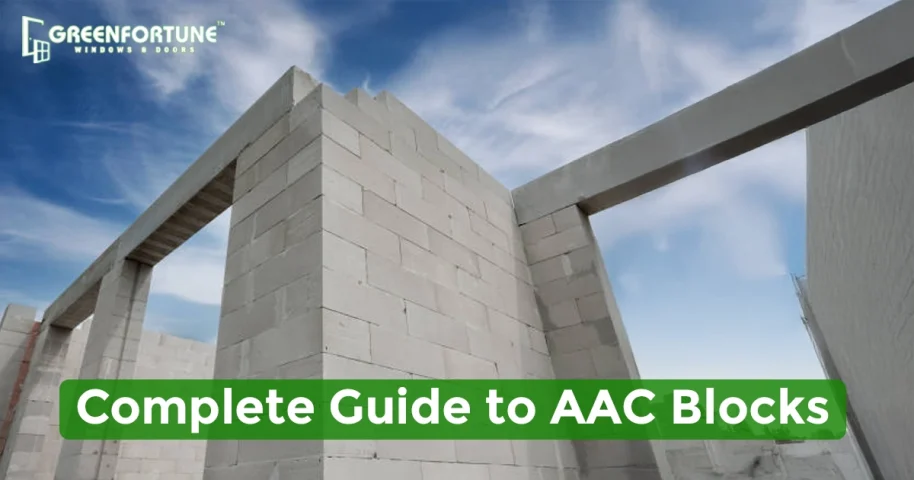

February 13, 2025Modern construction has seen one material gain increasing recognition due to its superior properties: Aerated Concrete Blocks, also known as AAC blocks. Crafted from autoclaved aerated concrete (AAC), these blocks boast benefits ranging from superior insulation to environmental friendliness. Understanding aerated concrete block sizes is vital when choosing the ideal material for any construction project, whether that be your home, office, or larger commercial complex.

This comprehensive guide covers everything you need to know about AAC blocks - their sizes, applications, and advantages - to make informed decisions regarding AAC blocks in your construction projects. This detailed blog will give you the ultimate idea of aerated concrete blocks, block brick dimensions and sizes and their advantages.

Table of contents

- What are AAC Blocks?

- Key Advantages of AAC Blocks

- Understanding Aerated Concrete Block Sizes

- Applications of AAC Blocks in Construction

- Autoclaved Aerated Concrete Block Price: Is It Worth the Investment?

- Why Opt for AAC Blocks?

- Explore the Benefits uPVC Doors and Windows for Your Construction Projects with GreenFortune!

What are AAC Blocks?

Before diving into AAC block brick sizes and prices, it's essential to gain a better understanding of their composition and utility. AAC, or Autoclaved Aerated Concrete, is an innovative lightweight building material consisting of cement, lime, sand and aluminium powder mixed in an Autoclaved Aerated Concreting environment, creating tiny air pockets within its construction, which make AAC blocks significantly lighter than traditional concrete or clay blocks.

These blocks are typically manufactured through an autoclaving process in which material is heated under pressure to give strength while keeping weight down. AAC block bricks have become popular construction materials due to their exceptional strength-to-weight ratio, with applications including walls, partitions, roofing and floors.

Suggested Read: uPVC Frame Door vs Wooden Frame Door

Key Advantages of AAC Blocks

There's no doubt about it that AAC blocks are one of the premier construction materials. Let's examine their key advantages as building materials:

Lightweight and Easy to Handle: Thanks to their unique aeration process, AAC concrete blocks are significantly lighter than their concrete counterparts, making them easier to transport, handle, and install.

Excellent Thermal Insulation: Thanks to their air pockets, AAC blocks offer excellent thermal insulation properties. They help maintain pleasant indoor temperatures while simultaneously reducing energy usage for heating or cooling purposes.

Fire Resilience: AAC blocks have natural fireproof properties, making them the ideal material for building structures resistant to flames. They're non-combustible and can withstand high temperatures without succumbing to ignition.

Sound Insulation: These blocks offer exceptional sound insulation properties, making them suitable for both residential and commercial buildings where noise reduction is a top priority.

Eco-Friendly: AAC blocks are made from natural materials with minimal environmental impacts during production. Manufacturing waste production is reduced, and the blocks themselves can be recycled after use.

Durability and Strength: Although lightweight, AAC autoclaved blocks are both strong and durable enough to withstand multi-story building loads without cracking under their weight.

Suggested Read: 10 Stunning Blue Bathroom Tile Ideas for a Stylish Space

Understanding Aerated Concrete Block Sizes

Now that we've discussed the advantages of AAC blocks, let's delve deeper into their various sizes, which are frequently employed in construction projects.

1. Standard AAC Block Sizes

AAC blocks are widely used for general construction projects and can vary slightly in size depending on their manufacturer. Below are the most frequently encountered AAC block dimensions:

600 x 200 x 100 mm (length x width x height). Also commonly referred to as 600x 200x 150mm and 600x 200x 200mm blocks, these bricks can be used for interior partitions, walls, and non-load-bearing applications such as non-load-bearing walls.

2. Full-Sized AAC Blocks

Full-sized AAC blocks are used to construct load-bearing walls or external construction projects. Their dimensions typically fall within this range.

These larger blocks are preferred for external walls as they offer improved insulation properties while being strong enough to withstand the load of any structure.

3. AAC Block Bricks

For smaller construction applications like partition walls or smaller builds, AAC block bricks make an excellent option.

These smaller bricks are easier to handle and commonly used for less-intensive structural works.

4. AAC Wall Blocks

These blocks are specifically designed for wall construction and provide outstanding strength and insulation properties. Common dimensions for these AAC wall blocks are - 600 x 250 x 200 mm. Due to their load-bearing capacity and insulation properties, they are particularly suitable for external walls, making them a cost-effective and versatile choice.

Suggested Read: Aluminium Windows vs uPVC

Applications of AAC Blocks in Construction

AAC blocks are highly adaptable, making them perfect for use in numerous construction applications. Here are some of their more frequently employed uses:

Walls: AAC concrete blocks can be used to construct both internal and external walls. Larger blocks should be used for external walls, while smaller bricks may be more suitable for internal partitions.

Partitions: AAC block bricks are ideal for partitioning rooms within buildings, whether in homes, offices, or commercial locations.

Floors and Roofs: AAC panels can be used as insulation in floor and roof systems, providing extra insulation while decreasing the overall weight of structures.

Structural Elements: Certain AAC blocks can also be used to create beams, columns, and other structural elements that require strength and stability.

Autoclaved Aerated Concrete Block Price: Is It Worth the Investment?

When selecting any building material, cost should always be evaluated carefully. While autoclaved aerated concrete blocks may cost more than traditional bricks or cement blocks initially, their long-term advantages make them more cost-effective in the long run.

Here's why:

Reduce Mortar Costs: Due to their lightweight nature, less mortar is required during construction, saving significant costs and energy consumption over time.

Energy Savings: Thanks to their excellent thermal insulation properties, AAC blocks provide long-term energy savings through decreased heating and cooling energy use, resulting in considerable long-term cost reductions.

Faster Construction: Larger and lighter blocks allow construction projects to move more quickly, cutting labour costs and project timelines in half. Given this advantage, many builders find AAC blocks offer excellent returns on investment when considering durability and energy efficiency.

Why Opt for AAC Blocks?

AAC blocks are an efficient and innovative choice for modern construction needs. Their numerous properties, such as thermal insulation, fire resistance, soundproofing, and strength, make them popular choices among residential, commercial, and industrial building projects alike. Being aware of different aerated concrete block sizes and their applications is essential in making an informed decision when selecting a suitable material for your project.

When selecting AAC block sizes for your project, be sure to consider all requirements carefully. Larger blocks are perfect for external walls, while smaller brick options, such as AAC brick options, are great for partitions. Don't forget about factors such as thermal insulation, soundproofing and cost when making your decision!

Investment in AAC wall blocks is ultimately an investment in energy efficiency, sustainability, and long-term quality. Whether for new construction or renovation project planning, AAC blocks offer durable structures that are eco-friendly, too.

Explore the Benefits uPVC Doors and Windows for Your Construction Projects with GreenFortune!

At GreenFortune, we recognise that selecting the right construction materials is essential for strength, efficiency, and sustainability.

As your trusted partner in premium uPVC windows and doors, GreenFortune is dedicated to delivering top-tier solutions that enhance the energy efficiency, aesthetics, and longevity of your home. Explore our wide range of uPVC window designs, tailored for superior comfort and lasting performance. Whether for renovation or new construction, let GreenFortune help you build a home that is as innovative and resilient as the materials you select.

Contact us today and experience the GreenFortune difference!