A Complete Guide to Flooring Construction: Methods, Best Practices & More

May 5, 2025

12 Unique Low Cost Home Design For A Budget-Friendly Living

May 5, 2025When it comes to building a home, some structural elements quietly play a big role behind the scenes. One such element? Lintels.

If you’ve ever noticed the strong horizontal piece above doors or windows, that’s your lintel doing some serious work. In this guide, we’ll explore everything you need to know about lintels in construction — from what they are to why they're essential, the different types, and how to install them the right way.

Let’s get right into it.

What is a Lintel?

In simple terms, a lintel is a horizontal structural member placed above openings like doors, windows, and arches. Its main job? To bear the load from the structure above and transfer it safely to the sides of the opening.

The term "lintels in construction" might sound technical, but it's a basic building block of both modern and traditional architecture. You’ll find them in brick walls, concrete frames, and even steel structures.

Lintels are different from beams — while both support weight, lintels are specifically designed for openings. They’re critical in ensuring the stability of your walls and the safety of your home.

Functions of Lintels in Construction

Lintels in building construction serve several practical and safety-related purposes. Here's what they really do:

1. Load Distribution

The primary role of lintels is to distribute the weight from the wall or roof above an opening to the adjacent wall portions. Without them, the load would directly hit the weak points of the frame.

2. Structural Integrity

They prevent cracks and structural failure around openings, especially in earthquake-prone or monsoon-heavy zones.

3. Aesthetic Framing

In many homes, especially modern homes, lintels double up as design elements. You can see exposed wooden lintels in rustic homes or sleek steel ones in industrial designs.

4. Ease of Construction

Lintels make it easier to align openings and maintain uniformity in wall elevations.

Variants of Lintels

There isn’t a one-size-fits-all approach to lintel construction. Here are the major types used in India and globally:

Type | Material | Best Used In | Pros | Cons |

Brick Lintels | Burnt bricks | Low-cost housing | Affordable, easily available | Low load-bearing, fragile |

Reinforced Cement Concrete (RCC) | Concrete with steel rods | Modern residential & commercial buildings | Strong, durable, fire-resistant | Requires skilled labor |

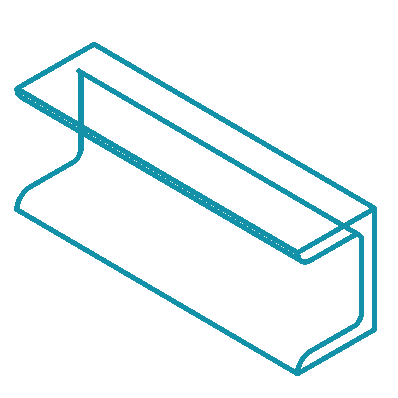

Steel Lintels | Rolled steel sections | Industrial buildings | Extremely strong, slender sections | Expensive, corrosion-prone |

Wooden Lintels | Timber | Traditional homes, cottages | Aesthetic, easy to work with | Termite risk, lower strength |

Stone Lintels | Granite, sandstone | Heritage structures, rural homes | Durable, classic look | Heavy, limited span |

When choosing lintels in construction, selecting the right variant is key to structural longevity and efficiency.

Factors to Consider When Choosing a Lintel

Selecting the right lintel isn’t just about material—it’s about matching the right solution to your structural needs. Here are the essential factors to weigh before making a decision:

1. Load Type and Weight

Understanding the type of load your lintel needs to carry is crucial. This includes:

- Dead Load: The permanent weight from walls, floors, or roofs above the opening.

- Live Load: Temporary or movable loads like people, furniture, or snow/rain accumulation.

Heavier loads, especially in multi-storey buildings, require materials like RCC or steel. Undersized or inappropriate lintels could result in cracks or structural sagging over time.

2. Span of the Opening

The width of the door, window, or passage impacts the lintel’s design. Wider openings increase the pressure on the center of the lintel, requiring stronger, stiffer materials.

- Up to 1 metre: Brick or timber lintels might suffice in non-load-bearing areas.

- 1 to 2.5 metres: RCC or pre-stressed concrete is usually the go-to choice.

- Beyond 2.5 metres: Steel or heavily reinforced concrete should be considered.

The wider the span, the more crucial it becomes to also account for deflection (bending). Oversight here can lead to aesthetic deformities or even functional issues like jammed doors.

3. Environment and Exposure

Climate and environmental conditions significantly affect material longevity:

- Humid or Coastal Areas: Use corrosion-resistant materials like RCC with anti-rust coatings or treated steel sections.

- Dry, Termite-Prone Zones: Avoid timber unless it’s specially treated and sealed.

- Seismic Zones: Reinforced lintels that allow for slight movement without cracking are ideal.

Even the direction your house faces (e.g., west-facing walls exposed to heavy rains) can influence which lintel material will perform best over time.

4. Aesthetics and Visibility

In visible areas, especially in open-concept or decorative homes, lintels can double as design features:

- Exposed Wooden Lintels: Great for traditional, rustic, or farmhouse aesthetics.

- Steel Lintels: Fit well in industrial or modern minimalist interiors.

- Stone Lintels: Best suited for heritage homes or where a classic, timeless look is preferred.

You can even use a cladding layer over lintels to match your interior or exterior design — combining strength with style.

Installation of Lintels: Step-by-Step Guide

Proper installation is key to ensuring the lintel performs well throughout the life of the building. Poor installation can lead to structural damage or failure over time.

Measurement and Planning

- Measure the width of the opening and calculate the bearing length (usually 150–200mm on each side).

- Choose the lintel type based on span and load.

1. Preparation of Opening

- Ensure the wall above the opening is supported during work using props or supports.

- Remove any loose material and level the surface where the lintel will rest.

- Ensure the wall above the opening is supported during work using props or supports.

2. Placement

- Place the lintel horizontally above the opening with adequate bearing on both ends.

- Use a level to ensure it is perfectly straight.

- Place the lintel horizontally above the opening with adequate bearing on both ends.

3. Sealing and Curing

- For concrete lintels, allow proper curing if cast on-site.

- Fill any gaps with mortar and waterproofing materials to prevent moisture ingress.

- For concrete lintels, allow proper curing if cast on-site.

4. Final Checks

- Recheck the alignment and load distribution.

- Once in place, remove temporary supports and inspect for cracks or signs of stress.

- Recheck the alignment and load distribution.

Final Thoughts

Lintels in construction might not be the most visible part of your home, but they’re one of the most important. From supporting your structure to adding design flair, these horizontal heroes play a major role in any building project.

Understanding how to choose, install, and care for your lintels helps ensure that your home stands strong — and looks great doing it.

Transitioning to a Lighter, Brighter Space?

Let Natural Light and Airflow in — with Green Fortune

While you’re upgrading your lintels in construction, consider how your doors and windows contribute to structural beauty and airflow. Green Fortune’s premium uPVC windows and doors not only enhance your home’s style but improve ventilation and insulation too.

Visit thegreenfortune.com and explore a range of solutions that go hand-in-hand with smart construction choices.

FAQs

- Can lintels be used in load-bearing walls only?

No, lintels are also used in framed structures to support partition walls and window openings. They provide both strength and shape consistency across levels. In some designs, they also serve decorative functions. - How long does it take to install a lintel?

For basic brick or wooden lintels, installation might take a day or less. For RCC lintels, expect at least a week due to the curing time. Time also depends on the size of the opening and the complexity of formwork. - What is the ideal thickness of a lintel in house construction?

It depends on the span and load, but generally, RCC lintels are around 100mm to 150mm thick. Structural engineers often calculate the size based on the IS codes. Undersizing can lead to structural damage over time.